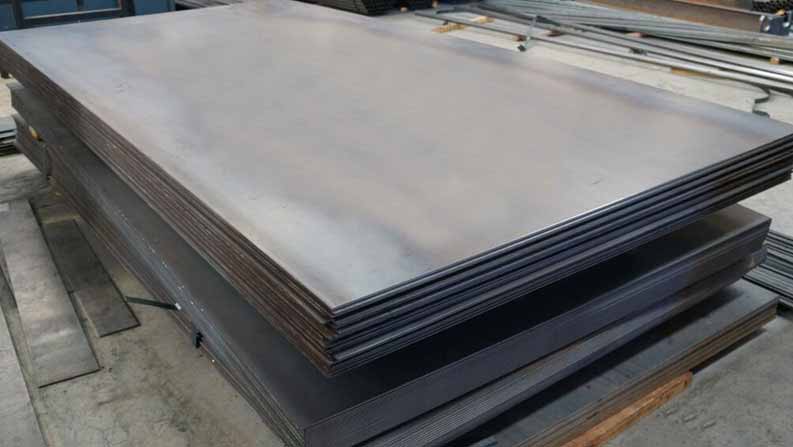

Looking for a high-performance wear-resistant steel that delivers longer service life under tougher abrasion conditions? Rockstar 450 is engineered for buyers who need higher hardness than 400-grade plates without sacrificing reliability or fabrication efficiency. Designed for demanding industrial environments, Rockstar 450 offers superior wear resistance, predictable performance, and excellent return on investment—making it a strategic choice for cost-conscious buyers worldwide.

Why Buyers Prefer Rockstar 450

Buyers prefer Rockstar 450 because it bridges the gap between standard abrasion-resistant steels and ultra-hard grades. It provides enhanced wear life while maintaining controlled toughness, which is essential for equipment exposed to continuous abrasion and moderate impact.

From a procurement standpoint, Rockstar 450 helps extend maintenance cycles and reduce unplanned shutdowns. Consequently, it supports higher productivity and lower lifecycle costs. Moreover, its consistent hardness and quality make it suitable for repeat orders and large-scale projects.

Key benefits that make Rockstar 450 a buyer favorite include:

- Higher abrasion resistance compared to 400-grade wear plates

- Nominal hardness of ~450 HBW, ideal for severe sliding wear

- Extended component life, reducing replacement frequency

- Good weldability with recommended procedures

- Reliable forming characteristics for industrial fabrication

- Cost-effective performance versus ultra-hard grades

As a result, buyers across mining, construction, and bulk material handling industries rely on Rockstar 450 for dependable, long-term performance.

Technical Specifications of Rockstar 450

Understanding technical specifications is critical for buyers when selecting the right wear-resistant steel. Below is a detailed overview of Rockstar 450 properties commonly supplied in global markets.

Chemical Composition (Typical %)

- Carbon (C): 0.18 – 0.26

- Silicon (Si): 0.20 – 0.60

- Manganese (Mn): 1.10 – 1.70

- Phosphorus (P): ≤ 0.025

- Sulfur (S): ≤ 0.010

- Chromium (Cr): 0.40 – 1.20

- Nickel (Ni): ≤ 0.60

- Molybdenum (Mo): ≤ 0.35

- Boron (B): Trace (to enhance hardenability)

This controlled alloy chemistry ensures uniform hardness, excellent abrasion resistance, and consistent quality across plate thicknesses.

Mechanical Properties

- Hardness: 420 – 480 HBW (Brinell)

- Tensile Strength: ~1350 MPa (typical)

- Yield Strength: ~1100 MPa (typical)

- Impact Resistance: Moderate, suitable for abrasion-dominant applications

These mechanical properties make Rockstar 450 ideal for environments where wear resistance is critical and impact loads are controlled.

Available Forms

- Wear-resistant plates

- Sheets

- Cut-to-size blanks

- CNC plasma- or laser-cut components

- Profile-cut parts as per drawings

Applications

- Mining and quarrying liners

- Crushing and screening equipment

- Chutes, hoppers, and transfer points

- Cement and aggregate handling systems

- Dump truck bodies and skip liners

- Recycling and bulk material handling plants

International Standards & Equivalent Grades

Rockstar 450 is a proprietary abrasion-resistant steel; however, buyers often reference international standards for comparison and approval purposes.

- UNS: No direct UNS designation (proprietary AR steel)

- ASTM: Comparable to ASTM A514 / AR450 (application-based equivalence)

- ASME: Similar performance to ASME SA514 for wear applications

- DIN/EN: Comparable to EN 10051 / EN 10204 wear-resistant plate standards

These references help buyers align Rockstar 450 with international project specifications and tender requirements.

Regional Market Focus

- India: Widely used in mining, cement, power, and infrastructure sectors

- Germany: Preferred for precision-engineered wear components and OEM fabrication

- UK: Strong demand in recycling, quarrying, and heavy fabrication industries

- UAE: High usage in construction, bulk material handling, and mining projects

Why Partner with Vandan Steel & Engg.co

For buyers, material quality alone is not enough—the right supply partner ensures consistency, documentation, and dependable delivery. Vandan Steel & Engg.co offers a buyer-centric approach to supplying Rockstar 450.

- Full Mill Test Certificates (MTCs) with every shipment

- Flexible MOQs to support both small and bulk orders

- Efficient domestic and international logistics solutions

- Expert technical support for grade selection and fabrication guidance

- Commitment to quality, traceability, and on-time delivery

By partnering with Vandan Steel & Engg.co, buyers secure a reliable supply chain and reduced procurement risk.

Source High-Performance Rockstar 450 – Contact Us Today

If your operations demand higher abrasion resistance, longer wear life, and measurable cost efficiency, Rockstar 450 is the solution that delivers. Work with a supplier who understands industrial challenges and buyer priorities.

Vandan Steel & Engg.co

???? 359 / 373, Flat -9, 2nd Floor, Minerva Mansion, Svp. Road, Khetwadi, Giragoan, Mumbai -400004.

???? +91-8828813630

✉️ [email protected]

Contact us today for pricing, technical consultation, and fast delivery—and strengthen your operations with wear-resistant steel engineered for performance and reliability.